- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Wenergy’s energy storage cabinets help businesses cut costs, enhance efficiency, and ensure reliable power. Scalable and high-performance, they integrate with existing infrastructure for peak shaving, renewable energy, backup power, and grid services. Globally certified and built for safety, our solutions deliver reliability across manufacturing, commercial buildings, data centers, and microgrids.

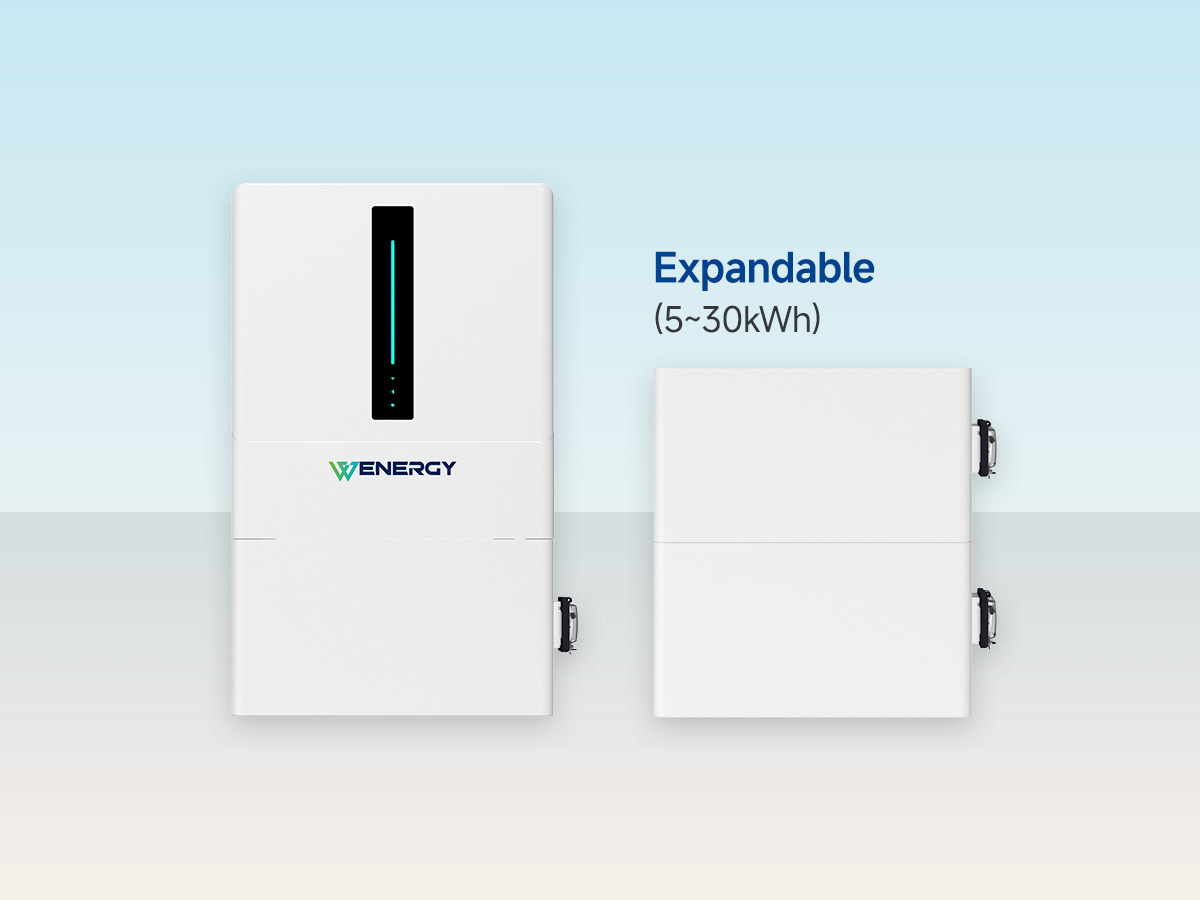

C&I Energy Storage Cabinet Portfolio

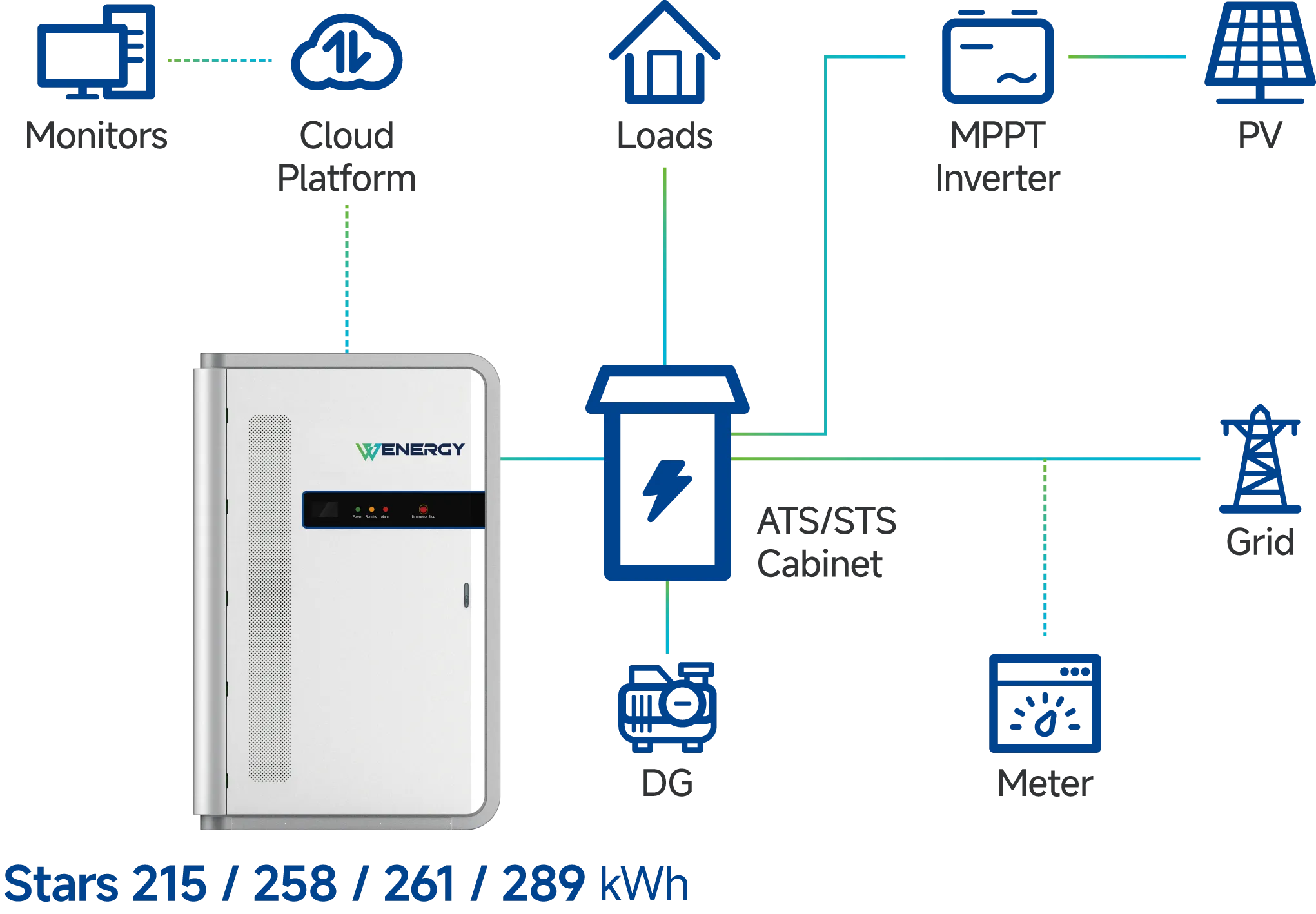

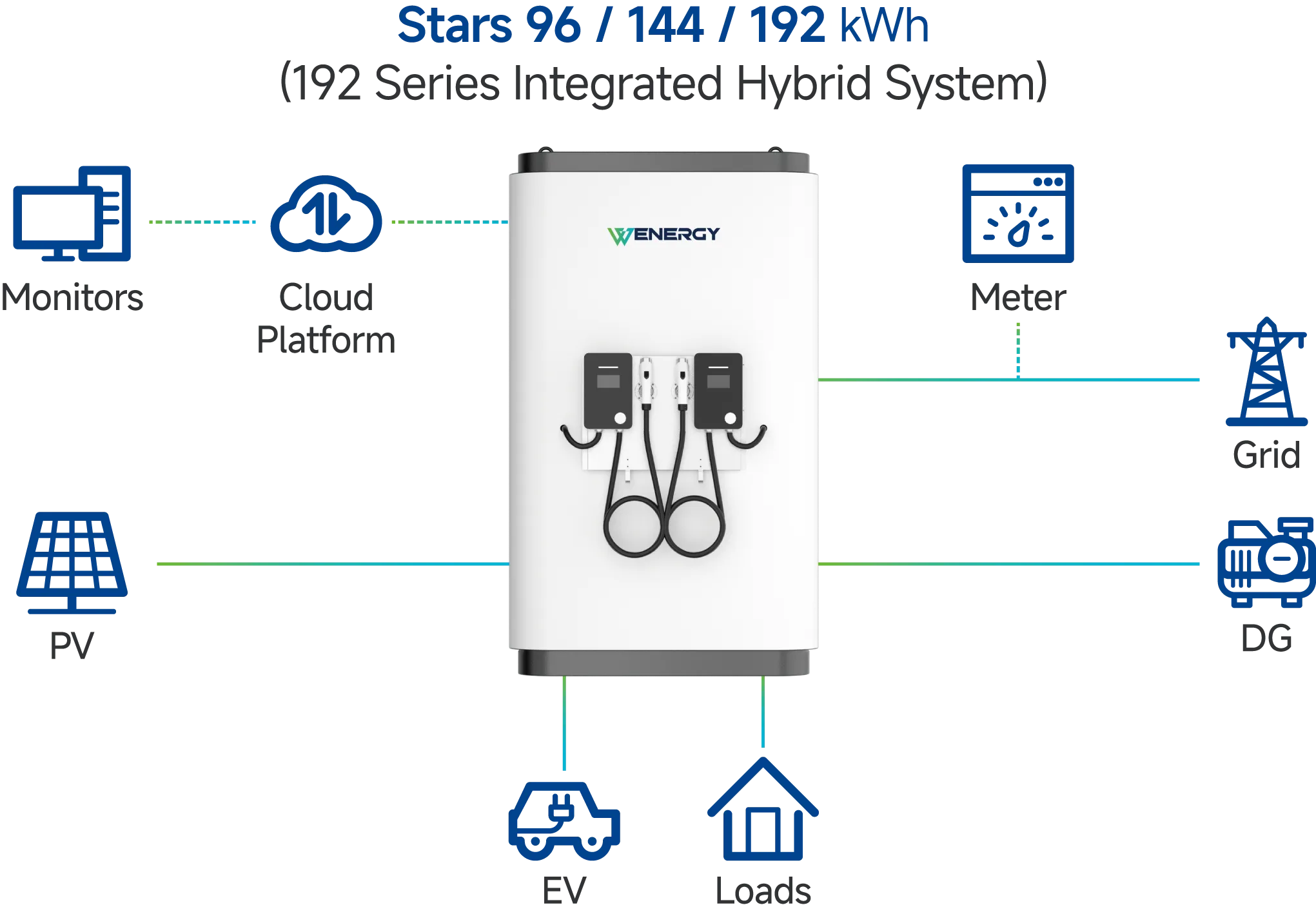

All-in-One Energy Hub

Energy storage with optional integration for MPPT, STS, ATS, and Charging GunOptimized ROI

AI-driven energy dispatch maximizes returnsSmart Cooling

Liquid cooling ensures efficiency and long battery life, operating reliably from -30°C to 55°CCertified Safety

Fully tested to IEC, UL, CE, TÜV, and DNV standards for safety, grid compliance, and performance

Key Functions & Applications of

Commercial Energy Storage System

- Peak-Valley Arbitrage

- Renewable Energy Integration

- Backup Power

- Grid Support Services

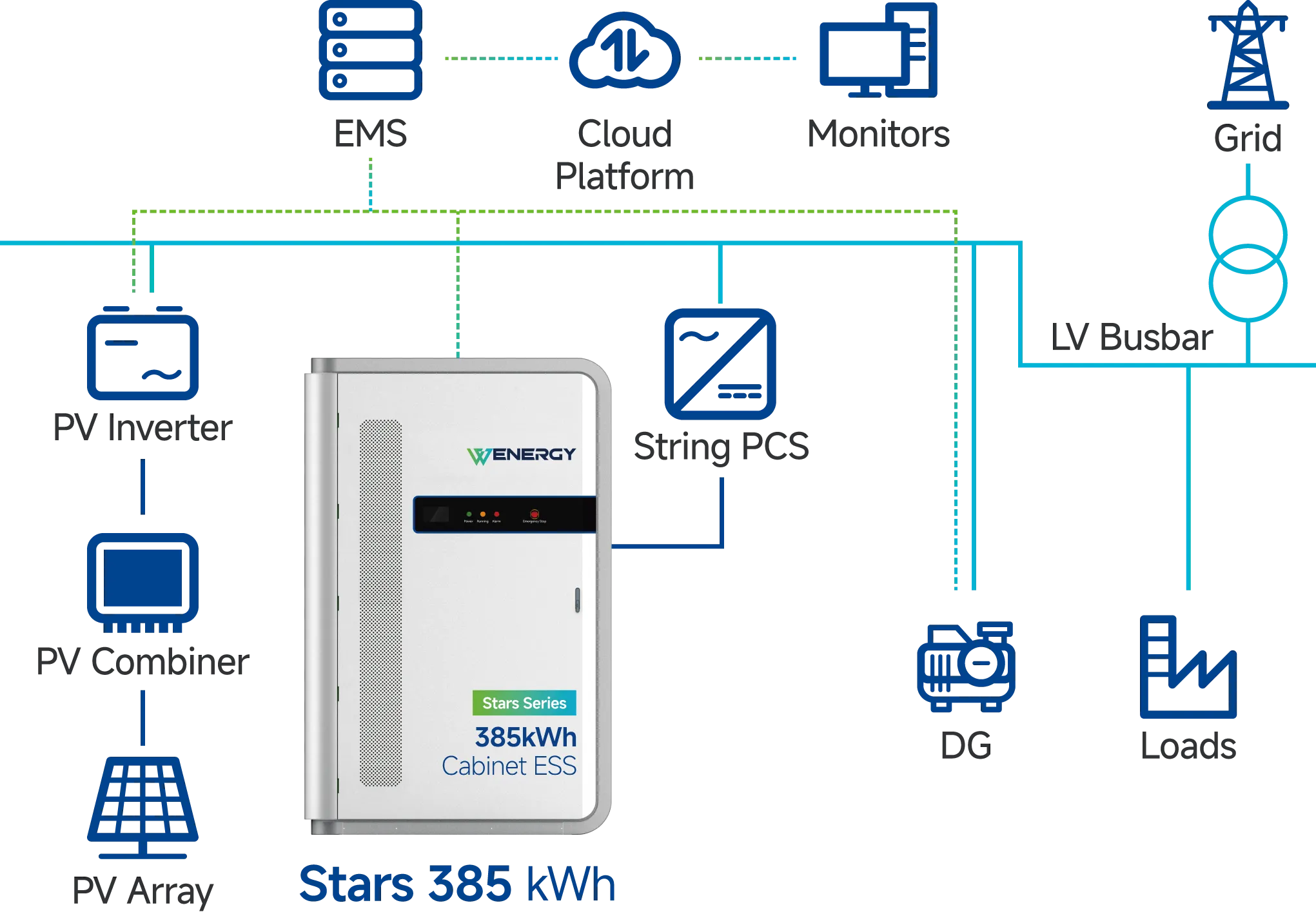

Topology Diagrams

- Compact AC-Coupled System

- AC-Coupled Hybrid System

- DC-Coupled PV-ESS System

Case Studies

Hear From Our Clients

Why Global Customers Choose Wenergy for C&I ESS Projects

Certified Safety & Reliability

Certified Safety & Reliability• Proven safety with 100+ global deployments and zero incidents

• 6S Security System with integrated PCS, EMS, and BMS control

• Certified to UL9540A, IEC 62619, and UN38.3 for global compliance

Advanced Hardware Performance

Advanced Hardware Performance• 125kW PCS for ultra-fast charge and discharge cycles

• Liquid cooling keeps cells within ≤3°C for longer battery life

• 314Ah cells deliver 30% more energy density in the same footprint

Intelligent Energy Optimization

Intelligent Energy Optimization• An AI-driven EMS maximizes ROI with real-time forecasting and control

• Seamless operation across grid, off-grid, and hybrid modes

• Sub-200ms response for critical grid frequency regulation

Global Deployment Capability

Global Deployment Capability• Pre-configured solutions allow project commissioning within 20 days

• Local inventory and service support across the EU and US markets

• Full EPC+Financing service model for streamlined project delivery

Focus on Innovation. Full-Chain Layout

With a vertically integrated supply chain, Wenergy controls every step from cathode materials and battery cells to pack assembly and smart ESS integration.This enables consistent quality, faster delivery, and optimized system performance for utility, commercial, and industrial energy storage applications.

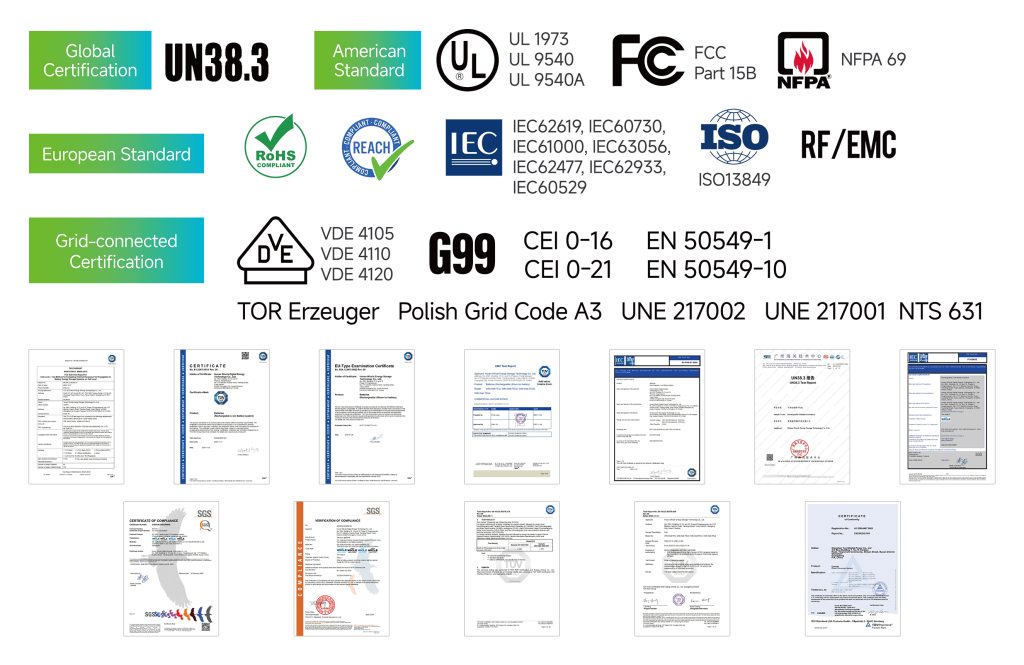

Certified Safety & Local Compliance

Wenergy’s energy storage systems meet major international standards, including UL, IEC, CE, UN38.3, ISO, and VDE certifications, ensuring product safety, reliability, and global market compliance.Our certified quality gives partners full confidence in every project—from design and manufacturing to on-site integration.

Core Strengths

• End-to-End Certification Coverage:

Cell → Module → PACK → System

• Full-Lifecycle Safety Standards:

Production → Transportation → Installation → Grid Connection

• Internationally Aligned Standards:

Compliant with major global safety and grid regulations

International Certifications

• Europe / International Markets

IEC 62619 | IEC 62933 | EN 50549-1 | VDE-AR-N 4105 | CEKey standards covering battery safety, system integrity, and grid-connection performance.

• North America

UL 1973 | UL 9540A | UL 9540System-level requirements ensuring battery safety, thermal runaway assessment, and fire protection.

• Global Transport & International Authorities

UN 38.3 | TÜV | DNV-GLEnsuring safe global transportation, multi-market access, and proven product reliability.

• China National Compliance

GB Standards | CQCRecognition of safety, grid connectivity, and quality under national regulatory frameworks.

Unlock Your Energy Potential – Reach Out Today!

Looking for a tailored energy storage solution?

Our experts are ready to discuss your needs and provide you with the best options for your business.

Get in touch now to start your journey toward a smarter, more sustainable energy future.

Frequently asked questions (FAQ)

1. What Are the Key Product Lines in Wenergy’s C&I ESS Portfolio?

Wenergy offers a versatile portfolio of commercial battery storage systems designed for different business and industrial needs:

96kWh / 144kWh / 192kWh / 215kWh / 258kWh / 261kWh / 289kWh AC-coupled cabinets – integrated with PCS for grid-connected applications such as peak shaving, PV self-consumption, and backup power.

385kWh DC-coupled systems – ideal for larger projects, especially solar-plus-storage plants.

Turtle M Series Mobile ESS (289kWh / 723kWh) – high-capacity, mobile energy storage solutions for flexible deployment in commercial, industrial, and off-grid applications, providing temporary power supply and enhanced mobility.

High-capacity models utilize advanced 314Ah cells, ensuring greater energy density, efficiency, and long-term reliability.

2. What Certifications Do Wenergy’s commercial energy storage systems Comply With?

As one of the trusted commercial energy storage companies, Wenergy ensures that every C&I ESS cabinet meets the highest international and regional safety standards. Our certifications cover:

- System safety and performance: IEC 62619, IEC 63056, IEC 62040/62477, UN38.3, RF/EMC, IP-rated protection.

- Grid connection compliance: CE (EU), UKCA, GB/T 34120-2017, EN50549, CEI 0-21/0-16, G99 (UK), VDE-AR-N 4105/4110/4120 (Germany), and NRS standards (South Africa).

These certifications guarantee that Wenergy’s commercial and industrial storage systems operate safely, reliably, and in full compliance with global grid codes.

3. How Long Do the Systems Last, and How Efficient Are They?

Wenergy’s commercial energy storage systems are designed for maximum efficiency—achieving over 89% for AC systems and 93% for DC systems. With a design life of 10 years and 8,000–10,000 charge/discharge cycles, our solutions deliver reliable long-term performance while keeping energy losses to a minimum.

4. What are the typical application scenarios for commercial battery energy storage systems?

Commercial and industrial energy storage systems are commonly applied in renewable energy integration, critical load protection, peak shaving, and cost reduction, as well as transportation and microgrid solutions.

Common applications include:

- Solar and wind farms: Store renewable energy, increase utilization, and smooth power output.

- Data centers and hospitals: Serve as backup power to ensure the continuous operation of critical facilities during outages.

- Manufacturing plants and commercial complexes: Support peak shaving, reduce electricity costs, and ensure operational stability.

- EV charging stations: Provide power during peak demand, reducing strain on the grid.

- Remote communities and island microgrids: Combine with solar or wind to achieve self-sufficiency and a reliable off-grid supply.

5. How Are the C&I Energy Storage Systems Installed and Maintained?

Wenergy, an experienced commercial energy storage company, provides comprehensive after-sales support that covers system installation guidance and maintenance training, ensuring long-term performance and peace of mind.

- Installation

- Place the cabinet on a 300 mm concrete base, level within ±5 mm.

- Connect directly with the built-in PCS and PDU—no extra assembly required.

- Maintenance

- Daily remote monitoring through the BMS.

- Annual on-site service: cell balancing, coolant check, and system diagnostics.

6. How Does a Commercial Energy Storage System Work?

A Commercial & Industrial (C&I) energy storage system works like a smart power bank for businesses. It stores electricity during off-peak hours when prices are low and releases it during peak demand, helping reduce grid reliance and lower energy costs.

7. How Can Deploying a C&I Energy Storage System Benefit My Business?

- Significant cost savings: Lower electricity bills by leveraging peak–valley price differences.

- Reliable backup power: Ensure uninterrupted operation of critical equipment during outages or grid failures.

- Enhanced renewable energy usage: Store excess solar energy from on-site PV systems and increase self-consumption rates.

- Sustainability and CSR: Reduce carbon emissions, support sustainable development goals, and strengthen your green corporate image.

8. What Is the Typical Payback Period for C&I Energy Storage Projects?

The payback period usually ranges from 3 to 7 years, depending on system size, utilization rate, incentives, and overall costs. Based on Wenergy’s past projects, we can provide tailored ROI assessments to help you make well-informed investment decisions.