- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Wenergy’s Large-Scale Energy Storage Solutions leverage advanced containerized battery systems to meet the demanding needs of modern grids and industrial users. Whether stabilizing the grid, integrating renewables, or optimizing onsite energy, our modular systems offer scalable, reliable, and cost-effective performance.

Ready to power your next project with reliable, high-performance energy storage?

Key Applications

- Utility & Grid Storage Solutions

- Distributed Energy Storage Solutions

Application Cases

View More Case Studies

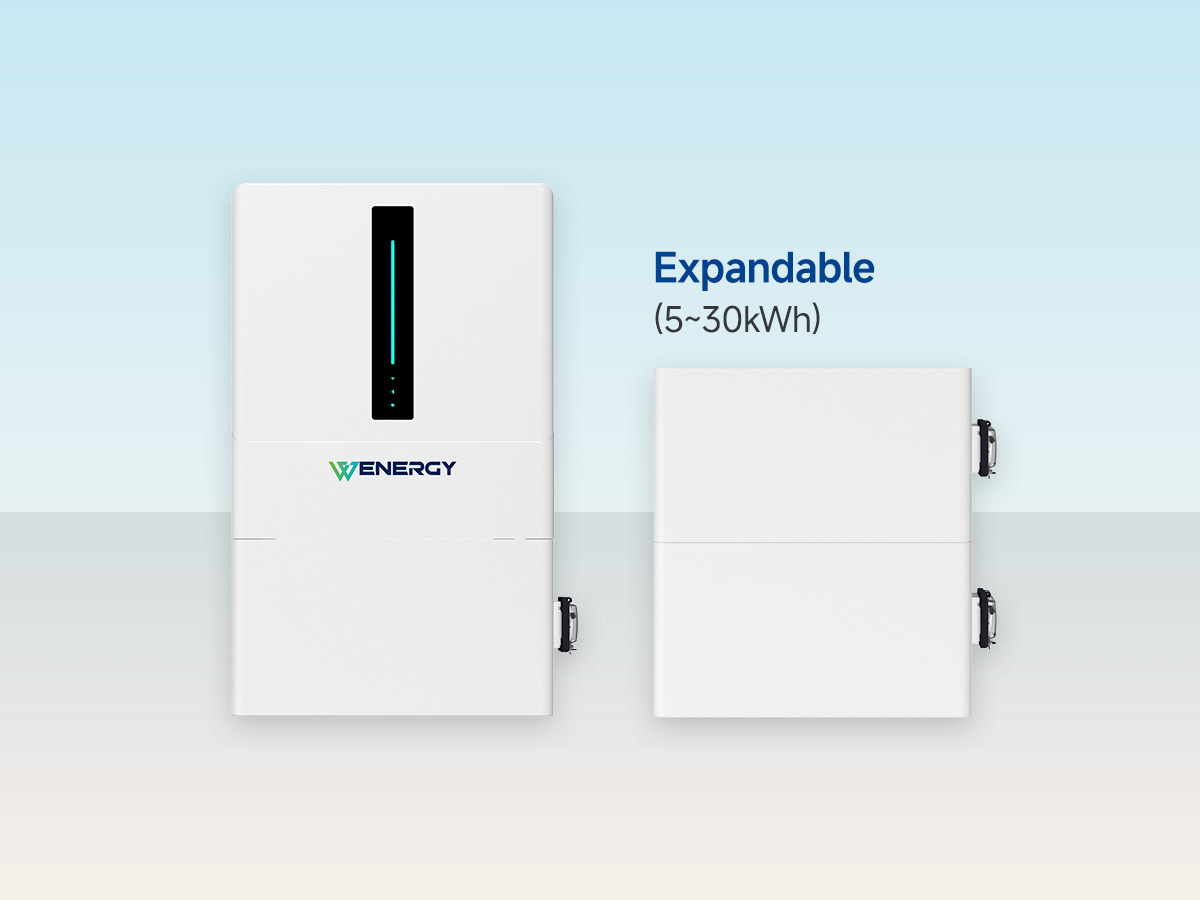

Featured Products

·High Energy Density

Maximize storage capacity in a compact design.·Modular & Scalable

Easily expand to meet growing energy needs.·Smart Management

AI-driven EMS for optimized performance and grid interaction.·Safety Certified

Complies with UL 1973 / UL 9540 / UL 9540A / IEC 62619 / IEC 62933 / CE / UN 38.3 / FCC / TÜV / DNV and more.

Why Wenergy Leads in

Large-Scale Energy Storage

Advanced Thermal Management and High-Voltage Architecture:

Advanced Thermal Management and High-Voltage Architecture:Liquid Cooling: Our proprietary liquid cooling technology efficiently manages thermal loads, enhancing performance and extending battery lifespan.

High-Voltage Capability: Supports voltages up to 1000V and PCS powers up to 120kW, ensuring high efficiency and broad application scenarios.

Intelligent Energy Management System (EMS):

Intelligent Energy Management System (EMS):AI-Powered Forecasting: Real-time monitoring and predictive maintenance, optimized for grid interaction.

Multi-Protocol Compatibility: Supports over 100 protocols and open API integration, ensuring seamless interaction with various grid systems.

Robust Safety and Scalability:

Robust Safety and Scalability:6S Security System: Comprehensive safety measures, including advanced fire suppression and leak detection, ensure reliability.

Modular Design: Flexible and scalable systems for easy expansion and integration with existing infrastructure.

Unified Control and Optimization:

Unified Control and Optimization:Cloud-Based BMS: Dual-processor architecture, 4KHz real-time monitoring, and 90% diagnostic coverage.

Unified Control Platform: Remote monitoring, cross-platform mobile access, and comprehensive health and performance analytics.

Energy Storage System Company You Can Count On

1

Headquarter in Singapore

5

Global Branches

14 Years

Battery Cell Manufacturing

660000 +m2

R&D and Production Base

15 GWh

Annual Capacity

Frequently asked questions (FAQ)

1. What is the system composition of Wenergy's containerized BESS?

Wenergy’s BESS containers integrate battery clusters (with Li-ion cells), a high-voltage PDU, DC combiner cabinet, liquid cooling thermal management system, and multi-level fire suppression (pack & container-level aerosol). The modular design supports 3.44MWh,3.85MWh to 5.016MWh configurations per unit, compliant with IEC/UL/GB standards.

2. What certifications do Wenergy's BESS products hold?

All systems meet:

International: IEC 62619, UL 9540A (fire), UN38.3 (transport).

Regional: GB/T 36276 (China), CE (EU), and local grid codes (e.g., UK G99).

3. What are the key safety features of Wenergy's BESS containers?

Our systems feature:

Three-tier protection:

Cell/pack/cluster-level BMS with overcharge/overcurrent/temperature monitoring.

Fire safety:

Dual aerosol suppression (≤12s response) + five-in-one detection (smoke/temperature/H₂/CO).

IP54/IP65 enclosures and fault-tolerant grounding per UL/IEC 62477-1.

4. What is the expected lifespan and warranty?

Design life: 10+ years (6,000 cycles at 80% DoD).

Warranty: 5 years (or 3,000 cycles) for batteries; 2 years for PCS/auxiliaries.

5. What are the transportation and installation requirements?

Weight: 36T (3.85MWh) / 43T (5.016MWh); sea/road transport (special permits needed for >40T).

Foundation: C30 concrete base (1.5x reinforcement for 5.016MWh).

Space: 6.06m(L)×2.44m(W)×2.9m(H); 20% land savings vs. 3.85MWh.

6. What after-sales support is provided?

Remote monitoring: 24/7 performance tracking via Wenergy EMS.

On-site: Certified technicians for commissioning/maintenance.

Spares: Global stock of critical parts (PDUs, cooling units).